Industrial automation is changing dramatically thanks to the introduction of robotic arms. This has a profound impact on the manufacturing process and production process. Thanks to the advancement of technology robotic arms, which are often called Arm robot industrial have become indispensable tools that provide unparalleled precision, efficiency, and safety across a myriad of industries. This article explores the many capabilities of robotic arms and their impact on the business environment in Australia.

Robotic arms, also known as robot arms, are a variety of mechanical devices created to replicate the human arm’s functionality but with greater precision and endurance. These automated solutions have found wide-ranging applications in industries like automotive manufacturing electronics assembly, pharmaceuticals, and many more, because of their ability to perform intricate, repetitive tasks with unmatched precision. The robotic arms are programmable. arms allows seamless integration into a variety of production environments. They offer a dynamic range of movement and flexibility to meet varying operating requirements.

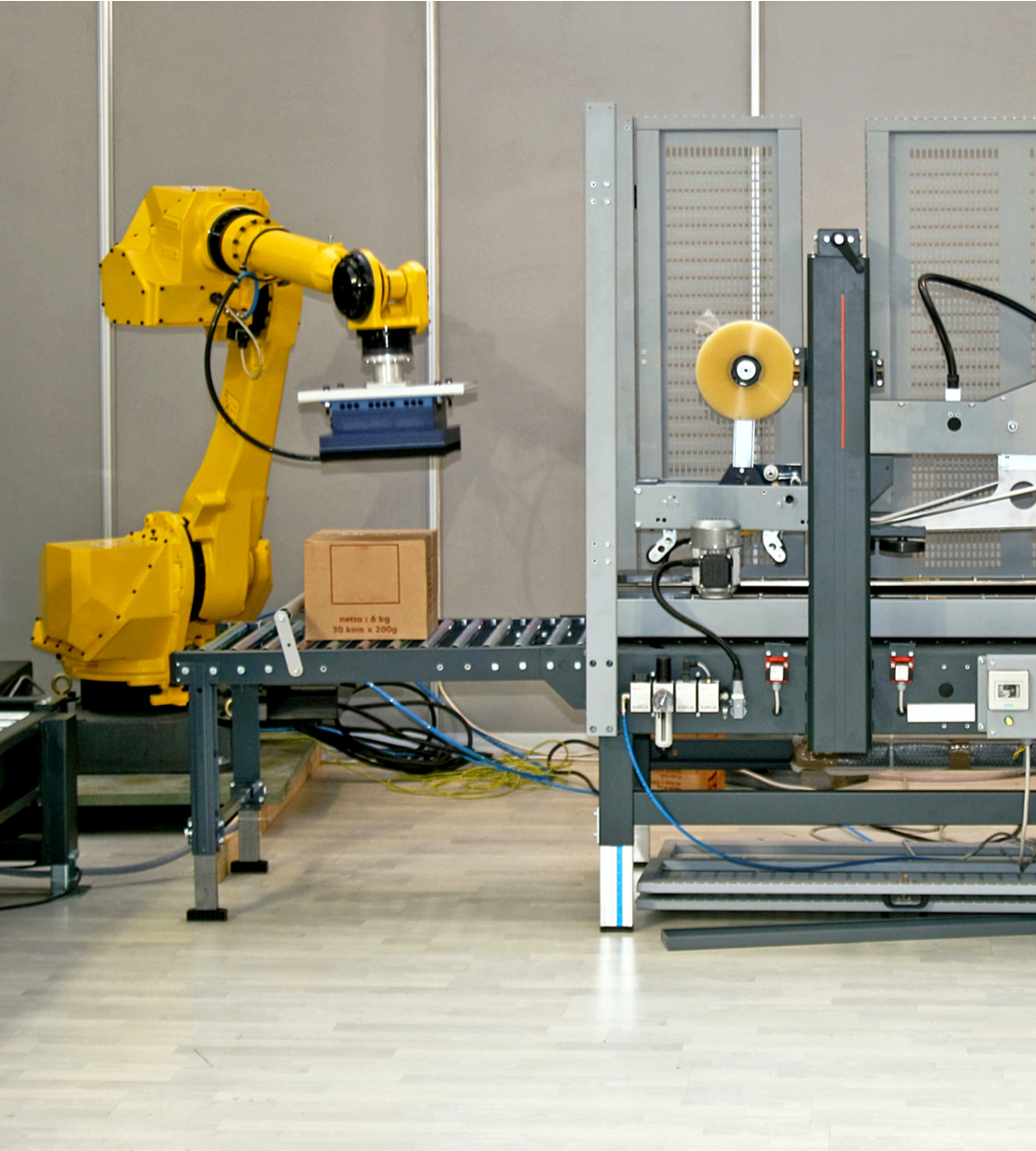

The robotic arm companies constitute the foundation of the modern day automation. They represent a sophisticated Kinematics Network of movable joints that can rotate and linear displacements. They also have amazing dexterity. The robotic arm can navigate intricate spatial configurations, operate objects with great precision, and make sure that humans. Robotic arms have become a necessity to the industrial sector and allow them to streamline manufacturing processes and improve productivity.

End effectors are the most important feature of robot arms. They function as the functional equivalent to human hands. End effectors, which are typically specifically designed for specific tasks have a major role to play in determining the nature of the applications that robotic arms can perform. Robot hands equipped with specific end effects can accomplish an array of tasks, from lifting and grasping heavy loads to delicately attaching intricate components.

The integration of robotic arms into manufacturing automation has led to an era of productivity and creativity. By harnessing the capabilities of robotic arms, companies are empowered to optimize their manufacturing processes, decrease human error and increase the overall quality of products. The seamless coordination between robotic arms and automated machines has resulted in significant improvements in operational efficiency. Click here Arm Robot Industrial

The effect of robotic arms extends beyond mere automation. It involves a major shift in the definition of industrial processes. Industrial robotic arms have not only transformed existing manufacturing workflows, but also opened the way for development of completely new production techniques. Robotic arms can perform in difficult and hazardous environments. This has improved the safety of workers while unlocking new opportunities for manufacturing processes that are complex.

The advancement of robotic arms technology has brought about the development of end effectors that are made to meet specific needs of industries. These high-tech end effectors equipped with cutting-edge sensory and gripping capabilities, have broadened the possibilities of use for robotic arms, enabling firms to meet a range of manufacturing challenges with unparalleled adaptability and accuracy.

Businesses in Australia have the unique opportunity to improve their competitiveness and operational capabilities as they embrace the potential of robotic arms automation. Integration of robotic arms into industrial workflows is expected to propel sustained growth, enhance overall productivity, and transform the way that manufacturing is conducted. Robotic arms are set to revolutionize industrial automation, focussing on high-end engineering and efficiency.

Conclusion: The introduction of industrial robotic arms or robotic arms represents a major leap in the field of industrial automation. Robotic arms, thanks to their unmatched precision, adaptability and safety features have redefined manufacturing in the modern age. They can provide companies with an edge in a market that is becoming more competitive. Businesses will reap the benefits as Australia takes on robotics technology. This includes an increase in productivity, operational efficiency and innovation.